Leading Vacuum System & Technologies Manufacturer in Korea | IVT

IVT CO., LTD specializes in supplying

high-tech products such as vacuum equipment, inspection equipment, and

precision parts related to semiconductor and display manufacturing. Established

in 2008. Recently, vacuum technology has

become a core cutting-edge industrial-based technology that spans several

industrial fields such as space engineering, biotechnology, material

engineering, and chemical engineering. Accordingly, in order to respond to the

diverse needs of their customers.

Its promises to become a reliable Main

Partner by doing their best to provide the best products through In addition,

as a partner of major national industries and national research institutes such

as Samsung Electronics Co., Ltd., Korea Institute of Standards and Science, and

the Nuclear Fusion Research Institute, IVT promise to do their best to localize

equipment/parts development projects.

Vacuum

Deposition Systems: It is equipment that vaporizes metal and non-metal materials in a vacuum

state using resistance heat, electron beam, and plasma and deposits them on a

substrate. Various heating elements (Sheath, Super Kantal, Halogen, and

Graphite) are applied in the vacuum chamber and a high vacuum environment is

provided.

E-beam

Evaporation System

• Single/Multi-Pocket

E-Beam source with Water Cooled Crucible (4 cc up to 75 cc) with individual

shutter

• High

Voltage Power Supply (3 kW to 15 kW)

• X-Y

Beam Sweep & Controller

• 4"Diameter

View Port on the Front Door with Manual Shutter

DC Magnetron Sputter: Available in single

& multi sputter sources with a water cooling system. Available in high

voltage power supply (3 kW ~ 10 kW) Substrate Rotation & Heating (100 ℃ up to 400 ℃) Source size from

3" to 8", User-defined source size available.

Vacuum

Furnace

• Working Temperature: 500 ℃ ~ 2,300 ℃

• Working Zone: 300 mm3 ~ 500 mm3

• Chamber Shape: cylindrical, rectangular,

and spherical

• Heater: sheath, super kantal, halogen,

graphite

• Atmosphere: vacuum, ar

• Auto Vent & Radiation Thermometer

Customized Vacuum

& Components: IVT

has been supplying various vacuum-based systems to domestic universities and

research institutes according to user design requirements and characteristics.

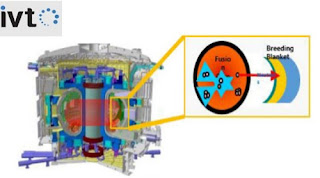

Li₂TIO₃Pebbles: The existing ceramic ball

production method has limitations such as ball size and impurity generation,

making it difficult to apply to the production method of growth material for

nuclear fusion reactors using lithium titanium oxide. Lithium Titanium Oxide

(Li2TiO3) is used as a tritium propagation material for fusion reactors. We

have developed a manufacturing system capable of mass production of 50 kg or

more per year.

Click here to contact us.

View more: IVT Leading Vacuum System &

Technologies Manufacturer

Comments

Post a Comment