IVT Ceramic Pebbles Specifications and features of Manufacturing system In Korea

Ever since our establishment in 2008, we are supplying

cutting-edge products including vacuum devices, testing instruments and

precision components exclusively for semiconductor and display manufacturing.

Vacuum technologies are the core fundamental covering extensive industrial

areas such as the space engineering, the biotechnology, the material

engineering and the chemical engineering. To respond various demands for such

fundamentals, we are producing/supplying various products from small devices

and large scaled equipment including vacuum devices for researches,

semiconductor testing devices, display process equipment, furnaces for

semiconductors and valves for chemical applications.

Vacuum technologies are the core fundamental covering

extensive industrial areas such as the space engineering, the biotechnology,

the material engineering and the chemical engineering. To respond various

demands for such fundamentals, we are producing/supplying various products from

small devices and large scaled equipment including vacuum devices for

researches, semiconductor testing devices, display process equipment, furnaces

for semiconductors and valves for chemical applications.

We have been accumulating our experiences and know-hows on

productions of precision components and advanced vacuum devices via cooperative

projects performed with other companies, universities and research institutes

for multiple years. Vacuum Display Process Equipment

Especially the intangible values are expected to be relatively higher due to

the technical support from the vacuum center, Korea Research Institute of

Standards and Science.

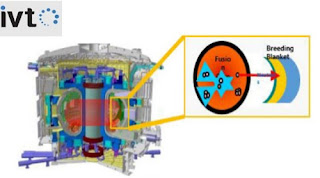

Ceramic pebbles

Ceramic (Lithium

Titanate) Pebbles

The existing ceramic ball production method has limitations

such as ball size and production of impurities, so it is difficult for

application in the production method of proliferation material for nuclear

fusion reactors using lithium titanium oxide. Lithium titanium oxide (Li2TiO3)

is used as the tritium E-Beam Evaporation System

proliferation material for nuclear fusion reactors. The company developed the

manufacturing system enabling mass production of 50kg or more annually.

Specification

·

Diameter: 1.0±0.05 mm

·

Roundness: < 0.05 mm

·

Purity: < 10 ppm

Applications

·

Breeding Blanket

·

For Fusion Reactor

Features

Pebbles

·

High thermal conductivity, stability

·

High chemical stability

·

High mechanical resistance

Manufacturing System

·

Patented dispensing & washing technology

·

Capacity: 50 kg per year

·

Fully automatic operation

Comments

Post a Comment