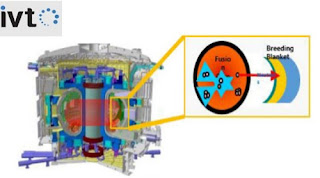

Overview of IVT DC Magnetron Sputter and E-beam Evaporation System of applications in Korea

Vacuum technologies are the core fundamental covering

extensive industrial areas such as the space engineering, the biotechnology,

the material engineering and the chemical engineering. To respond various

demands for such fundamentals, we are producing/supplying various products from

small devices and large scaled equipment including vacuum devices for

researches, semiconductor testing devices, display process equipment, furnaces

for semiconductors and valves for chemical applications.

We have been accumulating our experiences and know-hows on

productions of precision components and advanced vacuum devices via cooperative

projects performed with other companies, universities and research institutes

for multiple years. Especially the intangible values are expected to be

relatively higher due to the technical support from the vacuum center, Korea

Research Institute of Standards and Science.

DC Magnetron Sputter:

·

Available in single & multi sputter sources

with water cooling system.

·

Available in high voltage power supply (3kw ~

10kw)

·

Substrate Rotation & Heating (100℃

up to 400℃)

·

Source size from 3"to 8", User defined

source size available.

E-beam Evaporation

System:

·

Single/Multi Pocket E-Beam source with Water

Cooled Crucible (4 cc up to 75cc) with individual shutter

·

High Voltage Power Supply (3kW to 15kW)

·

X-Y Beam Sweep & Controller

·

4” Diameter View Port on Front Door With Manual

Shutter

Applications:

·

Material Analyses for Semiconductors and

Displays

·

Hydrogen Analyses on Automobile and Steel

Materials

·

Minimal Quantity Analyses of Ultra-Pure

Materials

In general, the inspection for impurity (outgassing rate)

due to the temperature increase is performed by using TDS. However, the local

and direction-oriented measurement and diagnose techniques on Dc

Magnetron Sputter Supplier impurity mappings of wafers in real-time

are not established until now while there is no system available for

simultaneous qualitative and qualitative analyses. We supply the TDS, the

product overcoming such disadvantages.

Performance

Comparisons:

TDS by IVT possesses higher compatibilities on Calibration,

Heating, Pumping Speed and others against that of other companies. Also,

depending on the applied area, DAQ software convenient for users is Thermal Desorption Spectroscopy

Korea provided.

Comments

Post a Comment